Green Evolution

Over the last 40 years, the ceramic industry’s approach to environmental and green issues has gone through a number of stages. From end-of-pipe measures using technological solutions to purify the various emission sources, there was a gradual shift towards the almost complete recovery and recycling of secondary materials. This was followed by the adoption of upstream environmental policy approaches involving the introduction of voluntary management standards that exceed regulatory obligations, covered by various European and international environmental product and process certifications. More recently, dematerialisation strategies have been developed to reduce the quantities of raw materials used.

Improving energy savings and efficiency

Since the 1970s, the Italian ceramic industry’s energy consumption per tonne of produced products has fallen from 10 to 6 Gigajoule thanks to technological innovations, improved production processes and energy efficiency of machines.

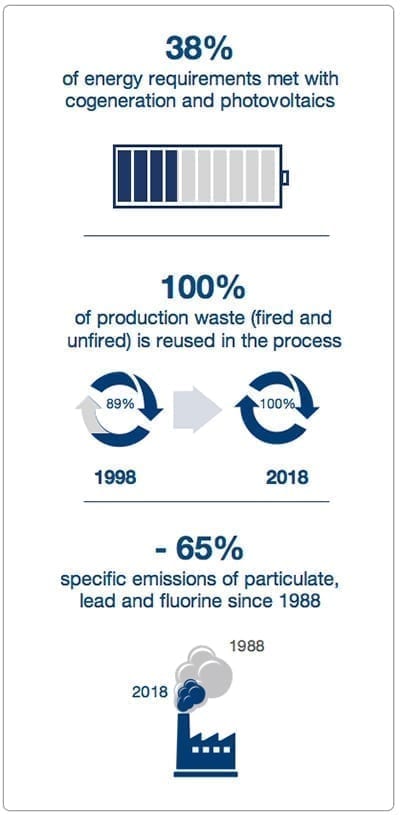

The industry is currently using more than 30 cogeneration plants and 4 photovoltaic systems with a power of 120 MW and an output of 450 GWh/year, equivalent to 38% of energy requirements.

An analysis of sector data reveals that 85% of factories have a lower unit consumption than the value associated with BATs (6.5 GJ/t).

Water and materials balance

Data for process water recovery reveal the Italian ceramic industry’s strong focus on these issues. No fewer than 97% of production sites have zero process water discharges, eliminating the risk of polluting surface and underground water. The reuse factor for fired and unfired production waste stands at almost 100% (compared to 89% in 1998) and for companies that use waste from other sectors (residues from incineration processes, cathode ray tubes, glass bottles, textile industry sludge, etc.) in keeping with a Cradle-to-Cradle approach, the corresponding figure is more than 100%.

Cutting emissions

As for polluting atmospheric emissions, the production plants in the Sassuolo district comply with national guidelines on Best Available Techniques (BATs).

Around 90% of Pb and F emissions are eliminated by treatment plants, while the figure for particulate is as high as 99%. Specific emissions of particulate, lead and fluorine from production plants have fallen by around 65% since 1988. Carbon dioxide emissions are concentrated in the range between 3 and 8 kg/m2 depending on the processing cycle and the type of product being manufactured. The sector participates in the European Union’s Emissions Trading Scheme (ETS), which establishes a community-wide system for trading CO2 emissions allowances (EU Allowances) and is therefore committed to achieving the European emissions reduction targets of -21% by 2020 and -43% by 2030.

Impact measurement and reporting and sustainability profile

With regard to the sector’s environmental reporting, in 2012 the Emilia-Romagna regional government signed an agreement with Confindustria Ceramica for the processing of environmental data. The agreement covers the processing of environmental parameters and emissions data communicated annually by companies through the regional AIA portal. The resultant report presents the results for various environmental impact and performance factors in terms of atmospheric emissions, water and water balance, use of materials and energy consumption. For assessment and reporting of the levels of impact and environmental performance, a total of 35 indicators are processed annually.

Mobility

A number of different solutions for improving the logistics of freight transport flows into and out of the Sassuolo district are at the assessment stage. The distribution system is prevalently based on ex-works deliveries, although other delivery modes are also present. The district currently uses rail transport for 24% of its supply and distribution flows, double the national figure. As for personal transport from home to work, some companies have begun experimenting with new forms of shared transport such as car-pooling.

December 2018

Sources of information – Regulatory references

- Report 2010-2015: Impact factors and environmental performance (Confindustria Ceramica, 2015)

- Italian ceramics for sustainability. Confindustria Ceramica – 2016 update

Architects

Architects