The Circular Economy (CE) is an approach that can be applied to any production system (from a single company through to complex systems) with the aim of minimising the raw material requirements and consumption (inputs) and waste generation (outputs) of production processes. By adopting processes of dematerialisation (smaller quantities of raw materials for the same uses/functions) and introducing reuse, re-fabrication and recycling flows capable of extending the lifetime and maximising the functionality of products and services, it is possible to fully exploit their value and avoid the consumption of new raw materials and energy. This eliminates the costs associated with the generation and disposal of waste and the related environmental and social impacts, while at the same time creating new product and service innovation opportunities in the various stages of optimisation.

For several years the Circular Economy has been a mainstay of the policies of the European Union, which in 2015 updated its key waste management guidelines for member states with a dedicated set of CE policies.

In Italy, starting out from the Environmental Bill associated with the 2015 Stability Law and the ad-hoc laws approved in several Italian regions (the first of which was Emilia-Romagna), the CE paradigm has begun to establish itself amongst public administrations and companies.

The ceramic production process: aspects consistent with the Circular Economy

• Reuse of internal production waste

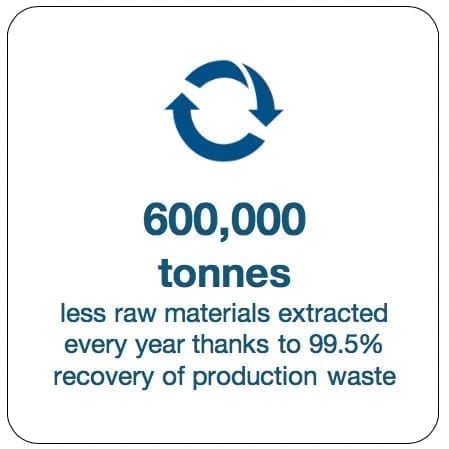

Unlike other production sectors, the ceramic industry is capable of reusing internally the majority of the residues generated during the production process. Thanks to advances in production technology, it is now possible to use most of the production residues (unfired waste tiles, fired waste tiles, washing line sludge, polishing and honing sludge, dried milling residues and exhausted lime) and reintroduce them into the ceramic production process in place of other raw materials. This avoids the extraction, transport and use of thousands of tonnes of materials of natural origin such as sands, feldspars, alumina, zirconium oxide, mullite and clays.

99.5% of the sector’s production and purification waste is reused in the production cycle, making up 8.5% of the mineral raw material requirements of the manufacturing process. Considering the Italian ceramic industry as a whole, the reuse of production waste avoids the extraction of an estimated quantity of more than 600,000 tonnes of mixtures of clays, feldspars and other materials.

With executive resolution no. 16604 of 23/10/2017 associated with the Regional Law on the Circular Economy, the Emilia-Romagna regional government identified four by-products originating from the ceramic sector that can be used effectively within the ceramic production process: “Unfired ceramic powders and bodies; powders from fired ceramics; unfired formed ceramic products (whole or fragments); fired formed ceramic products (whole or fragments)”. Inclusion on the list serves as a kind of guarantee for companies, informing them about the suitability of the production process they have adopted and helping them avoid raw materials consumption and waste production.

• Reuse of waste from other production processes

A further reduction in input raw materials is achieved by using waste materials originating from other production processes (glass waste, sludge from the textile industry, etc.).

• Advantages of using waste

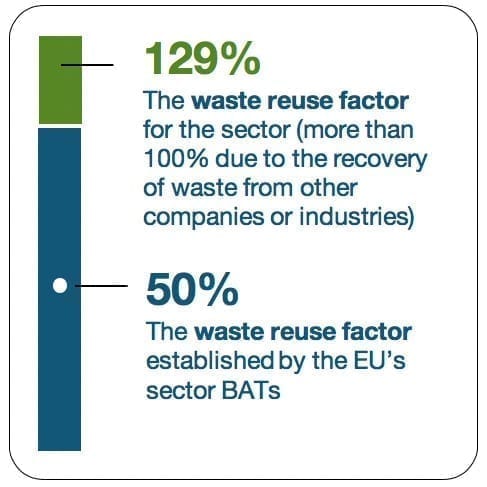

The reuse of production residues generated in ceramic production facilities and in external processes may occur according to various organisational schemes depending on the equipment present at the sites and the nature of the material. At a sectoral level, the average waste reuse factor stands at a value of 129%, well above the value of 50% specified by the sector BATs (Best Available Techniques identified by the EU).

Incentivising the reuse of materials in the ceramic industry also leads to a sharp reduction in movements of heavy vehicles used to supply raw materials, resulting in savings of fossil fuels and helping to reduce the production of greenhouse gases. At the same time a corresponding quantity of material is removed from the waste cycle.

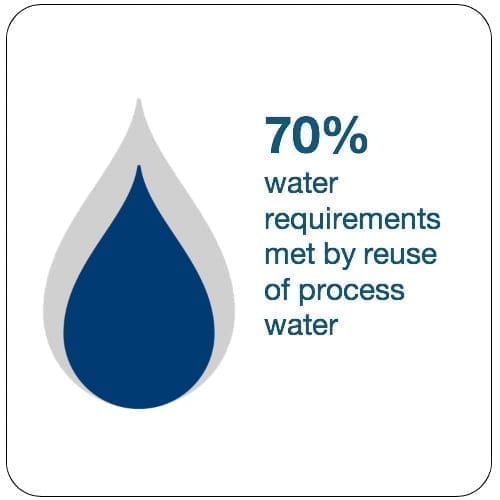

• Reuse of process water

Water consumption is another important aspect of the production process and occurs mainly in the operations of raw materials milling, glazing and fired tile finishing. Sector companies have been reusing wastewater for years with outstanding results, and 100% of wastewater is now recycled in the milling process.

In 2015, recycled wastewater made up almost 70% of the water requirements of the process, thereby reducing groundwater usage. The average recovery factor (the ratio of reused water to wastewater production) was 104%, reflecting the companies’ ability to use wastewater of external origin.

Ceramic products and the Circular Economy

Due to its intrinsic characteristics such as resistance to extreme atmospheric conditions, chemicals, humidity, temperature variations and UV rays, ceramic is an extremely durable material with an estimated lifetime of more than 50 years and is easy to recycle/recover in processes that reuse fired and unfired waste and demolition waste in accordance with a CE vision.

The development of product sizes and thicknesses to meet market demands also has repercussions in terms of overall environmental characteristics. In particular, the development of low-thickness ceramic products reduces the quantity of raw materials used (dematerialisation) and also reduces transport costs due to the lower weight of the materials as well as energy costs per square metre.

The recently introduced digital decoration process also leads to a drastic reduction in the quantity of decorative materials applied per square metre of ceramic products as well as further advantages in terms of overall environmental impact (e.g. reduction in water requirements), operator safety, reduced energy requirements and climate-changing emissions.

Future developments: a few examples of research paths

As for research, the Ceramic Centre of the University of Bologna has promoted a number of European projects involving sector companies and dedicated to the testing of new ceramic products with good characteristics of circularity. These include:

- The MATER_SOS project (Sustainable materials for the renovation and construction of new buildings) aims to lower the environmental impact of materials traditionally used in building such as concrete, mortar, tile adhesives, interior and exterior ceramic tiles and glazes by introducing more than 60% recycled materials into traditional formulations and reducing the energy consumption of production processes.

- The WINCER project has promoted the development of tiles that can be used to achieve significant savings of natural resources due to the complete replacement of feldspars and siliceous sands (100% saving) and partial replacement of clays (saving of more than 62%). This allows for a significant reduction in ceramic body preparation costs (savings of around 33%).

Sources of information – Regulatory references

- 2010-2015 report: Environmental impact and performance factors – Confindustria Ceramica

http://ambiente.regione.emilia-romagna.it/it/sviluppo-sostenibile/temi-1/autorizzazione-integrata-ambientale-aia/prestazioni-ambientali-delle-industrie-ceramiche - The New Big Circle – Boston Consulting Group

- Circular By Design, European Environmental Agency

- Growth Within – A Circular Economy Vision for a Competitive Europe, Ellen McArthur Foundation

- https://www.arpae.it/cms3/documenti/_cerca_doc/ecoscienza/ecoscienza2018_2/andrea_canetti.pdf

- https://www.arpae.it/cms3/documenti/_cerca_doc/ecoscienza/ecoscienza2018_2/giuliana_bonvicini_et_al.pdf

- http://www.matersos.it/

- http://www.wincer-project.eu/

January 2019

Architects

Architects

Construction firms

Construction firms