Tecnica

Ventilated façade anchoring systems | di Thomas Foschini

Considerations of an aesthetic, economic, energy and performance nature underpin the growing demand for installation of ventilated façades. Although a wide variety of materials can be used, Italian ceramic tiles are the ideal solution given their characteristics of flexibility, aesthetics, inertia, sustainability and durability. The choice of system used for anchoring the cladding panels to the external wall is crucial in terms of design potential, aesthetic performance and safety.

“Indirect” anchoring systems

The choice of anchoring system must meet regulatory requirements and take into account the needs of the client, the creativity of the designer and the capabilities of the installer. It must also consider aspects of aesthetics, economics and performance. The first thing to note is that the most technologically advanced anchoring systems proposed by the leading ceramic companies – which almost always commission specialist partners – are of an indirect type. In these systems, the ceramic panel is not anchored directly to the building’s structure but to a grid of vertical and horizontal profiles (which in turn are fixed directly to the external wall) together with a series of brackets, rivets and accessories of various kinds.

Exposed or concealed?

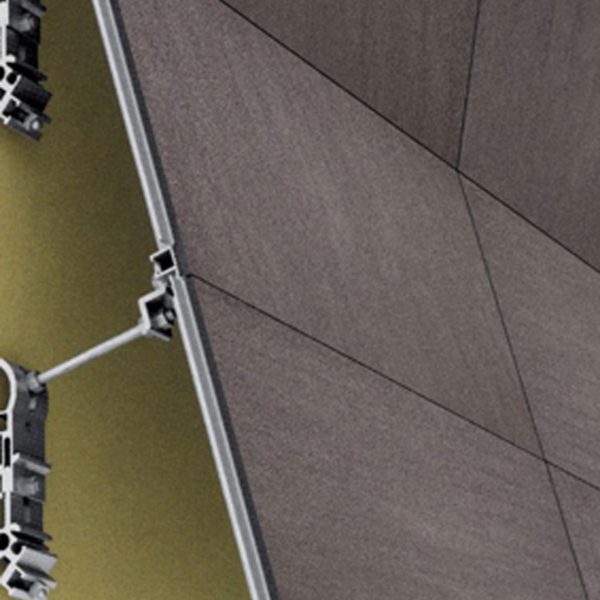

The anchoring systems used for ventilated façades are divided essentially into two large families. In the case of exposed anchoring systems, the ceramic panels are supported and connected to the underlying substructure by means of classic L-shaped stainless steel brackets which project outwards from the structure and support the front and sides of the ceramic panel. When available, the brackets are chosen in the same colour as the ceramic panels to make them less conspicuous. Concealed anchoring systems are the most innovative solution – or more accurately family of solutions – in terms of both technology and design freedom because they allow the architects and designers to create a seamless, uncluttered external façade.

In both cases, the presence of a substructure (made of aluminium or of steel in the case of high loads) facilitates the correct façade layout, where the joints can be arranged vertically, horizontally or even staggered. The cavity between the cladding panels and the loadbearing wall behind them (which can be as much as 15 cm or more) allows air to circulate and can also be used to house a thermal and acoustic insulating panel. By integrating fixed and sliding points, the installer is able to correctly size the joints, a crucial factor for achieving a perfectly aligned façade and a flawless aesthetic appearance.

What is concealed behind the ventilated “package”?

The anchoring system is a collection of parts made up of brackets fixed to the building wall (placed at greater or lesser intervals depending on the loads they have to bear in terms of panel weight and wind force); vertical profiles fixed to the brackets; and a horizontal grid (in the case of concealed anchoring systems). A fibreglass net is almost always present to support the panel in the event of accidental breakage, making it easier to replace it and improving the safety of the building when pedestrian and vehicular traffic is present below.

Concealed anchoring systems always require a preliminary phase of panel preparation in order to accommodate the special steel inserts necessary to connect it to the grid below. In the case of concealed anchoring systems, the aluminium or steel vertical profiles are fixed to slotted horizontal profiles, which in turn are shaped to withstand wind load more effectively.

Once the substructure has been fixed to the wall in accordance with the design specifications, the installer mounts the ceramic panels by hooking the brackets onto the horizontal profile and then tightening the screws located on the adjusting brackets until the joints are the correct size.

Panels, or rather “modules”

Developing an industrial process for preparing the cladding panels and the modules that will be used to hold them is the ultimate challenge for companies in the sector. Even the smallest differences between the levels and values stipulated in the design project and those that are actually present on site may create serious issues during installation and compromise the final aesthetic result. For this reason, to limit costs and avoid construction site delays, a number of Italian ceramic companies are offering solutions in which the panel is preassembled in-factory by applying metal profiles.

Pre-assembly in the ceramic panel/module manufacturer’s facility brings at least three advantages: savings in the use of connecting materials; greater working precision thanks to the use of numerically-controlled machines; and much more flexible management of joints (creating patterns that extend over the entire façade) and sizes (including the possibility of zero-width joints, essential for creating a “continuous surface”). Another important aspect is the fact that whatever the preference of the architect and client in terms of visual wall effect, modern ventilated façade installation systems are capable of achieving it.

Large thicknesses and sizes

Another way to avoid complex anchoring systems (rivets, dovetail grooves, etc.) when using cladding panels with a thickness of at least 2 cm is to perform special millings on the sides and corners of the panels which will serve to accommodate the steel clip (which is in any case concealed despite replicating in principle the more traditional exposed anchoring system). Aesthetic quality and low cost together with greater impact resistance of the large-thickness panels make this solution a valid alternative to the more advanced anchoring systems, whether concealed or modular with metal profiles.

In general, all the options described above allow for the use of larger sizes than in the past. Compared to the early ventilated façades where the main panel size used was 60×60 cm, the development of modern anchoring systems and the increase in size of Italian ceramic panels allows for the installation of a considerable range of sizes up to 60×120 cm (together with submultiples and strips, 30×120 cm, 90×90 cm, etc.) and in some cases even larger square and rectangular formats. The potential to create a wide variety of patterns in keeping with the needs of the specific project allows for the highest degree of creativity and customisation.