Italian ceramic tiles are produced in under an hour but last for over 50 years. Their compact surface is the result of an innovative industrial process that combines high levels of performance with care for the environment. Their extremely low porosity guarantees excellent technical quality in every respect. Italian ceramic tiles are resistant to impact, wear, abrasion, aggressive chemical agents, thermal shock and water infiltration and do not require extensive maintenance.

A long-lasting material

The average lifetime of Italian ceramic tiles is 50 to 60 years. A comparative analysis conducted by the Department of Engineering Science and Methods of the University of Modena and Reggio Emilia has shown that other types of indoor flooring materials have a shorter lifetime. Resin floors have an average lifetime of 10 years, while LVT and carpet last for 15 years, resulting in higher environmental costs in terms of both production and end-of-life disposal.*

The secret lies in firing

Firing is at the heart of Italian industrial ceramic tile production.

Prior to this stage, the raw materials undergo the following transformations:

- Clay, sand, feldspar and other materials are ground in rotary mills together with water (including recycled water) to form a clayey, fairly viscous liquid slip solution.

- The slip comes into contact with very hot air, which causes the water in the body to evaporate leaving a very fine granular spray-dried powder.

- The spray-dried powder is pressed in moulds and transported to the kilns for firing.

Once pressed, the tiles acquire their final qualities during the firing process. This process occurs at temperatures of between 1000°C and 1300°C* and gives the finished products their typical characteristics of strength and durability. The natural bodies are transformed into products with high technical and aesthetic qualities. The surface decorations and glazes crystallise to give Italian ceramic tiles their final colour.

Reduction in fluorine and particulate emissions

Since the 1970s, the Italian ceramic tile industry has worked hard to improve the environmental impact of its production cycles, in which firing plays a crucial role. As required by National Guidelines on Best Available Techniques (BATs), all industrial facilities are equipped with advanced technologies for abating pollutants. This has resulted in a drastic reduction in atmospheric emissions of CO2, dust, lead, sulphur, particulate and fluorine.

(approx. 82% reduction between 1988 and 2020)

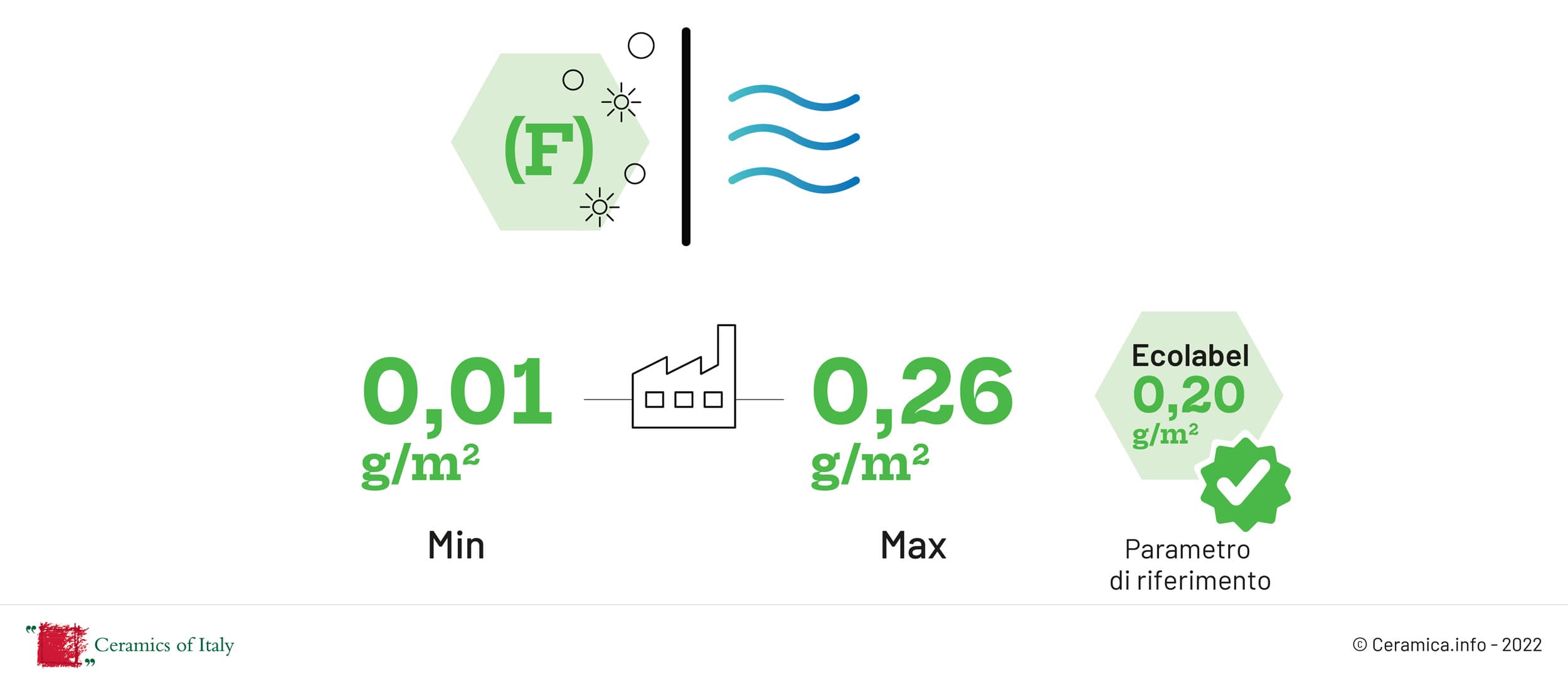

Fluorine is one of the typical pollutants released by industrial kilns. The quantity released from the ceramic tile firing process varies between 180 and 340 kg/year, depending on the size of the plants. However, the installation of hot dust and fume purification systems has enabled the Italian ceramic tile industry to strictly control the fluorine emissions in its production cycles and keep them below the legal limit of 0.2 g/m2 required for Ecolabel certification.

FEF – ATMOSPHERIC FLUORINE EMISSIONS

Period 1988 – 2020

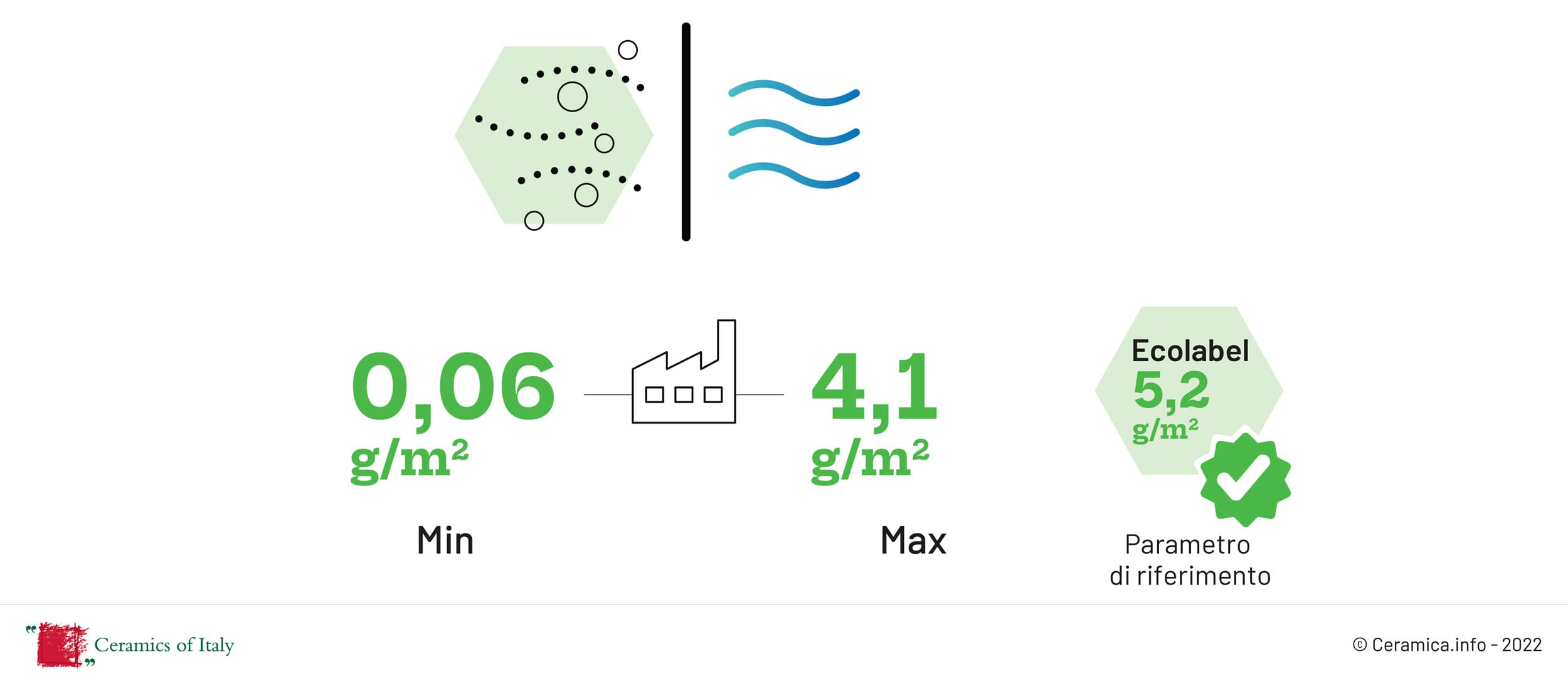

In addition to fluorine, a pollutant that is typically produced during the firing stage, the Italian ceramic tile industry has also intensified its efforts to treat particulate matter emissions. The maximum values measured for all plants investigated are below 60% of the benchmark levels of the industry BATs.

FEF – ATMOSPHERIC PARTICULATE EMISSIONS

Year: 2020

Durable means sustainable

Italian ceramic tiles are friendly to the planet because they originate from production processes with minimal emissions and need less frequent maintenance and replacement than other materials. Their longer lifespan reduces the use of natural resources and transportation of products to markets all over the world, thereby lowering the environmental impact of the entire supply chain.

Architects

Architects

Construction firms

Construction firms

Dealers

Dealers

Installers

Installers

Public

Public